Choosing the right fabrics is a crucial step for anyone working in the textile industry, from fashion to furniture. Knowing the composition and characteristics of materials allows you to make informed choices, ensuring quality and satisfaction to end customers. Manifattura Foderami Cimmino teaches how to read and interpret information on the composition of fabrics, with a particular focus on percentages and symbols often found in labels.

Table composition fabrics

Here is a useful table to understand the composition of the most common tissues and their main applications:

This table is a basis for identifying the most common materials in the textile market. However, it is important to delve into the differences between natural, synthetic and mixed fabrics.

Guide to tissue composition

Understanding the composition of textiles is essential for those working in the textile industry. This directly affects the properties of the material, its application and the maintenance required. Correct interpretation of the information on labels can make the difference between a product suitable for use and one that is intended to disappoint customers.

How to read the composition of tissues

Textile labels are essential for knowing the characteristics of a material. Usually, the composition is given in percentages showing the ratio of different fibers present. For example, a fabric with 80% cotton and 20% polyester is considered a blend, appreciated for the combination of comfort and strength.

Steps to interpret a label:

- Read the percentages: Look for the predominant material to understand the main characteristics of the fabric.

- Identify additional fibers: Synthetic or elastic fibers, such as elastane, may be present in small percentages to improve the fit.

- See symbols: The symbols on the labels give instructions for washing, drying and ironing.

Understanding this information is particularly useful for textile professionals who have to ensure the quality of the final product.

Percentage of textile composition

Composition percentages directly influence the quality and use of a fabric. Here are some common combinations and their meanings:

- 100% cotton: Natural, soft and breathable fabric. Ideal for casual wear and linen.

- 50% cotton, 50% polyester: A balanced mix of comfort and resistance. Perfect for shirts and garments resistant to frequent washing.

- 97% cotton, 3% elastane: Added stretch for a better fit, typical of jeans and tight pants.

- 100% polyester: Durable and versatile, but less breathable. Often used for sportswear and accessories.

These percentages may vary according to the specific needs of the producer or consumer. A blended fabric can offer the ideal compromise between aesthetics, functionality and durability.

Symbols composition fabrics

In addition to the percentages, it is important to know the symbols that accompany textile labels. Some of the most common include:

- Basin symbol: Indicates the maximum recommended washing temperature.

- Circle with a “P”: Indicates the possibility of dry cleaning.

- Triangle: Inform about the possibility of bleaching the fabric.

- Iron: Shows if the material is suitable for ironing and at what temperature.

Interpreting these symbols correctly is essential to keep the tissues in good condition over time. It also helps manufacturers to provide clear instructions to their customers.

Guide to textile materials

Textiles are the beating heart of any fashion, furniture and industrial project. Understanding the characteristics of fabrics, their origins and specific applications is crucial to choosing the product that best suits the end customer’s needs. This section explores the main differences between natural, synthetic and mixed fabrics, offering useful tools for a conscious selection.

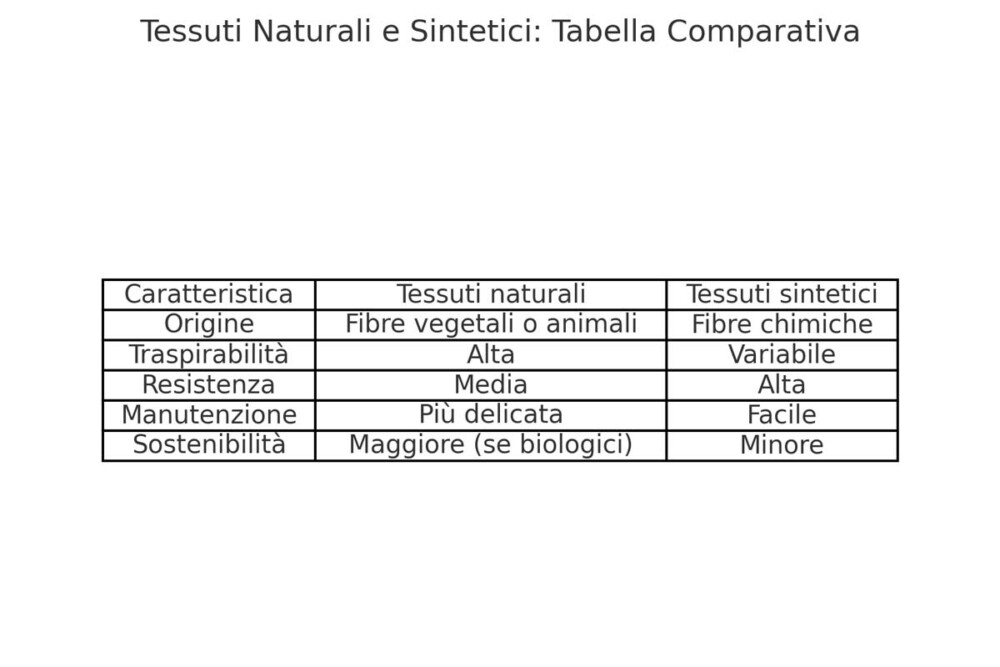

Natural and synthetic fabrics: comparative table

Knowing these differences helps you choose the right material for each project, considering both performance and environmental impact. For example, natural fabrics are ideal for garments intended for warm climates due to their breathability, while synthetic fabrics excel in technical and durable applications.

Difference between natural and mixed fabrics

Natural fabrics, such as cotton, linen and wool, are appreciated for their breathability and comfort. However, they may require more attention in maintenance. Mixed fabrics, on the other hand, combine natural and synthetic fibers to offer the best of both worlds: resistance, elasticity and practicality.

An example is the stretch fabric, which often combines cotton and elastane for a comfortable and durable effect. This type of fabric is particularly used in the fashion industry, where flexibility and durability are essential.

Composition of textiles and clothing

In the clothing industry, fabric composition plays a crucial role. A garment made of natural fibers will be ideal for those looking for comfort and sustainability, while technical fabrics are perfect for those who need high performance, as in the case of active & streetwear.

Some examples:

- Casual clothing: Natural fabrics such as cotton and linen.

- Technical clothing: Polyester and nylon for strength and lightness.

- Elegant clothing: Mixed with viscose for a soft and silky effect.

Here too, knowing the characteristics of materials helps meet end-user expectations.

Significance of tissue composition

Understanding the composition of fabrics means ensuring that each choice is fit for end use. This not only helps to avoid errors in production, but also improves customer satisfaction. For example:

- A mixed fabric with high polyester content is ideal for corporate uniforms that must withstand frequent washing.

- A 100% natural fabric is perfect for high-end sheets or summer clothing.

In conclusion, knowing materials is a fundamental skill for those working in the B2B sector, since it allows to optimize every phase of the production process and guarantee the highest quality to customers.